What are conveyors?

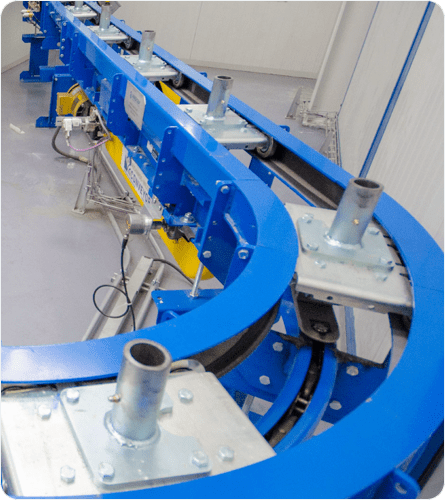

Conveyors, or material handling systems, are mechanisms used in coating application processes to efficiently transport materials, products, or goods within a facility. These systems allow for the automated and continuous movement, separation, and classification of items, facilitating a constant and organized flow of materials between different stages of production or storage.

We improve global industry through

specialized engineering and advanced technology.

Importance of conveyors

Conveyors are an essential solution in modern industry, enhancing the efficiency, safety, and cost-effectiveness of internal material handling operations. Their ability to move products continuously and automatically, combined with their adaptability to different product types and spaces, makes them a valuable asset across a wide range of industrial and commercial sectors. With proper planning, the installation of conveyors allows companies to streamline processes, increase productivity, and improve competitiveness in the marketplace.

At ANAEROBIA, we can assist you in selecting from a variety of conveyor configurations and types, taking into account production times, the weight and dimensions of the parts, available space within your facilities, as well as production volume.

Experience: Our team has the necessary training and expertise to face the challenges of the industry.

Local Support: We are present in the country’s industrial hubs to provide close and timely assistance to our clients.

Standards: Our equipment complies with international and national regulations.

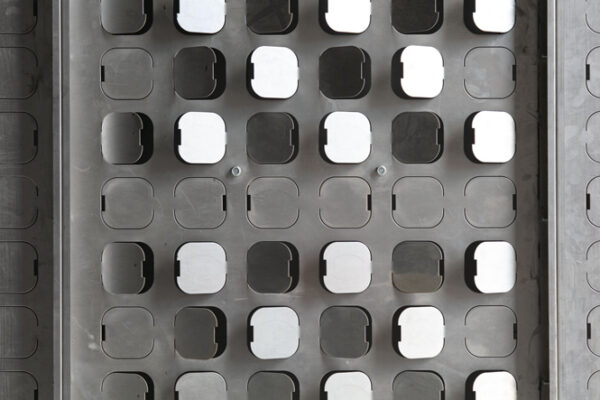

Types of conveyors

There are different types of conveyors, each adapted to specific needs based on the type of material to be transported, weight, speed, and work environment. Conveyors can be classified according to the following criteria:

• Overhead or elevated:

I Beam

Closed Track

• Floor or ground level:

Closed Track

Roller Table

Chain and/or Belt Conveyor

• Manual (Free)

• Semi-automated (Indexed)

• Automated (Power & Free)

• Material handling systems with robots

Advantages of conveyors

Production agility:

They automate the continuous movement of parts along the production line, enhancing process efficiency.

Maximum performance:

They optimize time, reduce costs, and improve operational efficiency.

Versatile movement:

They adapt to straight, curved, or inclined paths according to the available space.

Increased safety:

They reduce accidents by avoiding direct handling of heavy or hazardous materials.

STANDARDS

Our conveyors comply with international regulations and meet quality and safety requirements.

We develop transportation systems tailored to the specific needs and demands of each client to ensure compliance with international standards (NFPA, OSHA, ETL, FM GLOBAL, ATEX, etc.).

Qualified and experienced team: Project Managers certified by IPMA.

If you require additional information, please send an email.

BUSINESS PARTNERSHIPS

Experience that supports us.

FAQ'S

The choice depends on the size, shape, and type of part to be painted. The most common conveyor is the overhead system, used to hang parts and optimize flow between stages. Drag chain conveyors are ideal for cylindrical parts, belt conveyors for small parts that cannot be hung, and roller or pallet conveyors for heavy or large-volume components.

Yes, Anaerobia provides custom conveyors as part of their painting application systems, designing and manufacturing tailored conveyors according to the specific needs of each client to integrate seamlessly into their paint lines.

To select the appropriate conveyor for a paint line, consider:

• Type and size of the parts

• Application process (liquid or powder)

• Production volume

• Required speed

• Capacity and weight of the parts

• Available space

• Level of automation needed

For example, overhead systems are ideal for large parts and continuous lines, while belt or chain conveyors are better suited for small or cylindrical parts. The key is to choose the system that best fits the workflow, plant conditions, and technical specifications of the process.

Industrial conveyors can handle a wide range of load capacities, from just a few kilograms to several tons, depending on their design, materials, structure, and motor. For example, belt conveyors typically handle light to medium loads, while roller or chain conveyors are designed for very heavy loads.